What is smart industry ?

What is smart industry ?

The industry is currently undergoing an unprecedented transformation, marked by the integration of digital technologies into production and management processes.

This evolution, known as Smart Industry or Industry 4.0, aims to create intelligent industrial environments with connected systems capable of communicating with each other.

The goal is to increase the efficiency of industrial processes while responding to new energy and operational challenges that the industry is facing.

Improve the performance of production tools

Improve the performance of production tools

Increase the efficiency of industrial processes with IoT and M2M solutions

Ensure high-performance production tools

- Improve energy performance

- Connect your machines wirelessly

- Perform remote maintenance operations

IoT sensors serving Industry 4.0

IoT sensors serving Industry 4.0

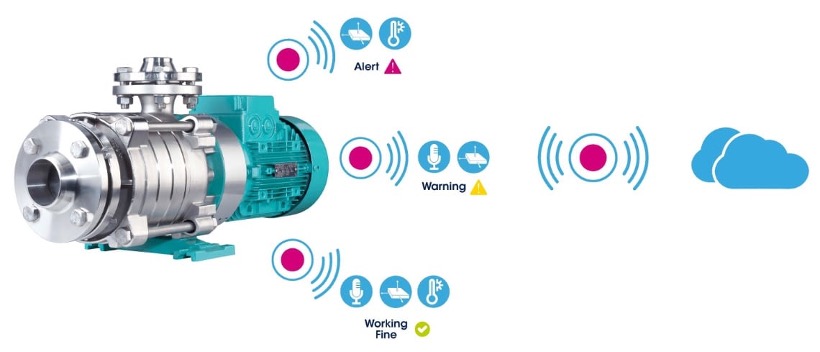

Optimizing production

The goal of any manufacturer is to reduce failure rates and increase the availability of their production equipment. Without equipment monitoring, they have no choice but to implement corrective or preventive maintenance. IoT sensors can analyze a machine's vibration signature to prevent potential malfunctions and send an alarm. This allows you to implement preventive maintenance to reduce the costs associated with unexpected repairs and increase the availability of your machines.

Vibration analysis

IoT vibration analysis uses wireless sensors attached to machinery to monitor vibrations, sending real-time data to the cloud for analysis. In the first case, they will have to wait for the equipment to malfunction before intervening on the machine, for example to replace a component. In the second case, the manufacturer will have to schedule periodic inspections to check whether or not there is a fault with the machine.

IoT solution - predictive maintenance

IoT technologies (LoRaWAN, Sigfox, etc.) make it possible to automate various machine performance indicators. Rather than periodically visiting the site to take readings and perform diagnostics (at the risk of going on site for no reason), IoT offers automatic and periodic monitoring of these KPIs.

On the one hand, the building manager will be able to install wireless, non-intrusive sensors without having to run cables. IoT services are perfect for this application as they can incorporate an accelerometer, a temperature sensor, and communication.

This is especially true since, when the status of a rotating machine changes, vibration drift is the first measurable symptom, well before noise, temperature, and smoke.

On the other hand, they will be able to retrieve the data from their sensors on a global, decentralized monitoring platform to analyze the values. Our IoT platform will provide this functionality with a dashboard dedicated to this use case.

Improving energy performance

Reducing energy consumption is one of the main challenges facing large industrial companies and the planet.

Remote reading sensors enable accurate monitoring of the energy consumption of various equipment. By detecting deviations from consumption forecasts, these sensors enable rapid identification of anomalies (leaks) and allow for corrective actions.

The installation of sub-meters will also enable you to segment your energy consumption and identify the most energy-intensive areas.

Create a healthy working environment

IoT sensors can be used to monitor air quality and measure temperature and humidity to create a healthy working environment that promotes productivity.

They can be combined with noise sensors to fight noise pollution, thereby improving the well-being of on-site teams.

Secure your goods

Effectively protect your stock of goods with IoT solutions. Installing magnetic contact sensors will allow you to receive an alert in the event of an intrusion.

Leak sensors will allow you to anticipate and react quickly in the event of water damage.

Ready to transform your industry ?

Our experts are available to assist you with your digital transformation projects, tailored to the specific needs of your industry.